DFM – Design for Manufacturing

We understand the importance of manufacturability. At WEILAN, our Manufacturing Feasibility Engineering team reviews each project from multiple perspectives.

We believe the earlier we get involved, the greater the value. Our team supports your product from the concept design stage to ensure it is manufacturable and efficient.

Design Analysis from Concept to Manufacturing

We update our analyses throughout the entire product design refinement process and follow our standard procedures until a complete and reliable report is delivered for manufacturing.

Our services include:Material shrinkage analysis, Wall thickness optimization, Parting line design, Gate and runner system design, 2K molding, Insert molding, IML analysis.

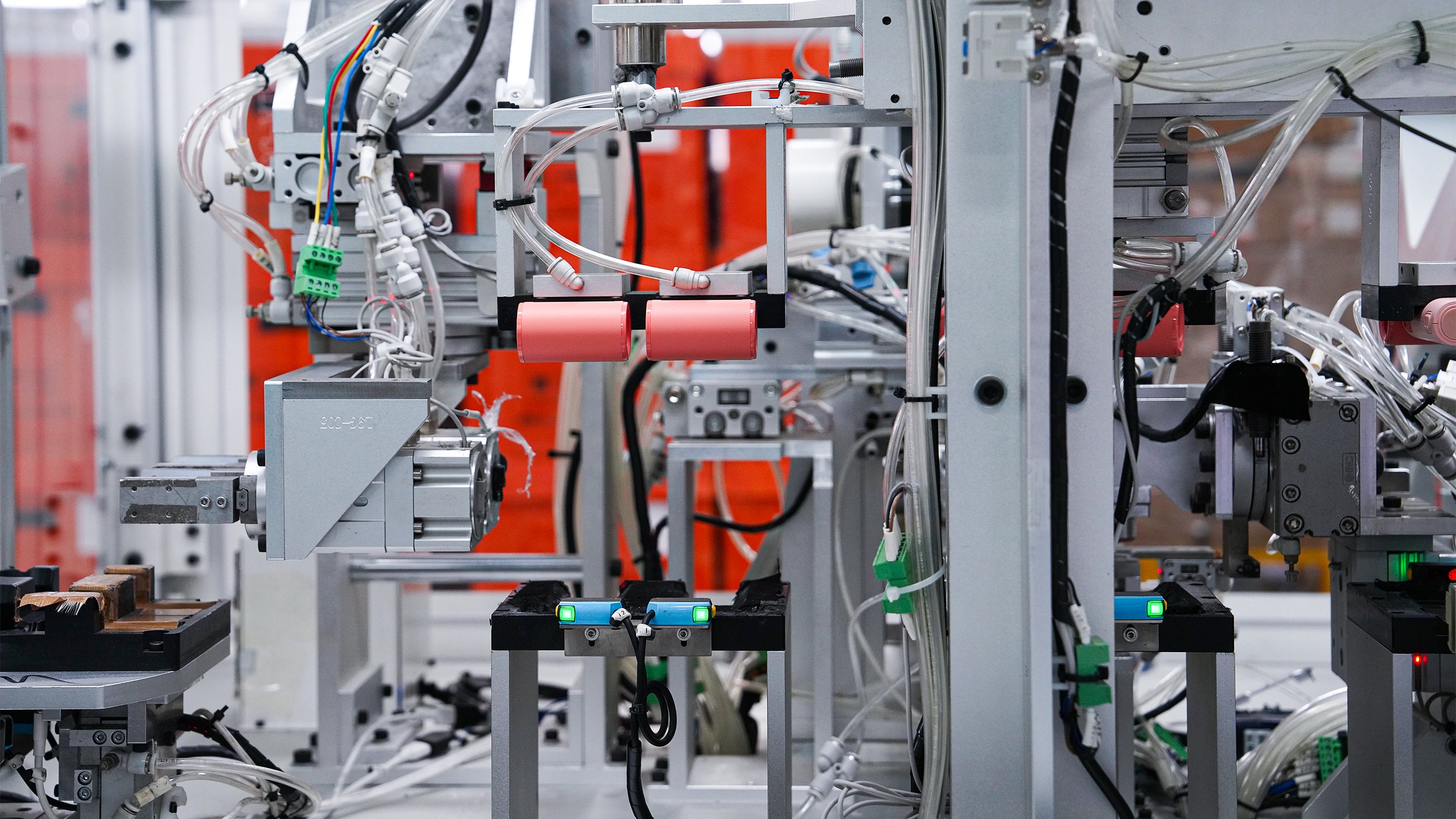

Smart manufacturing solutions.

Drafting and demolding analysis, Rib and post design evaluation, Ejector system design.

Tolerance and assembly checks Surface finishing analysis covering painting, silk screen printing and electroplating.

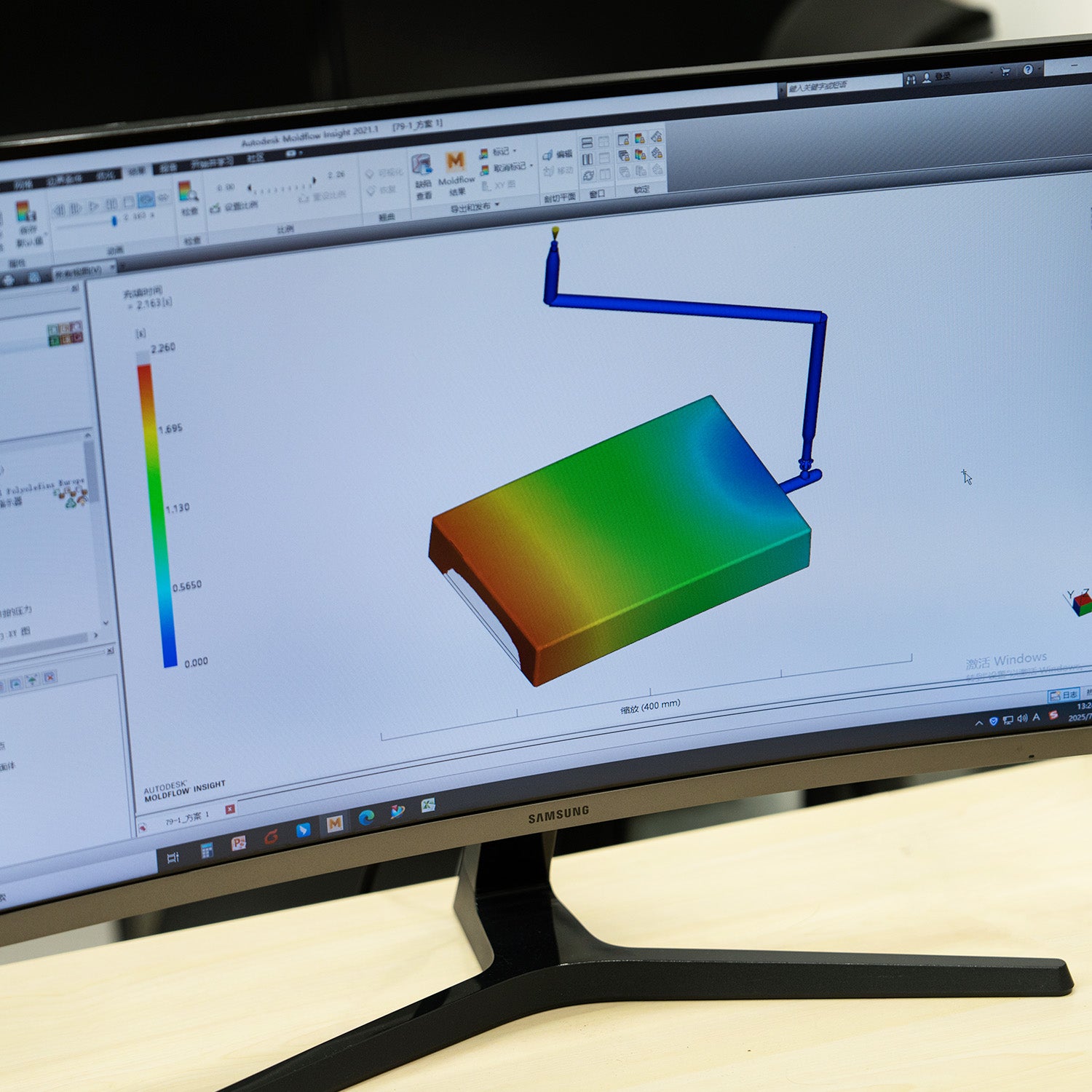

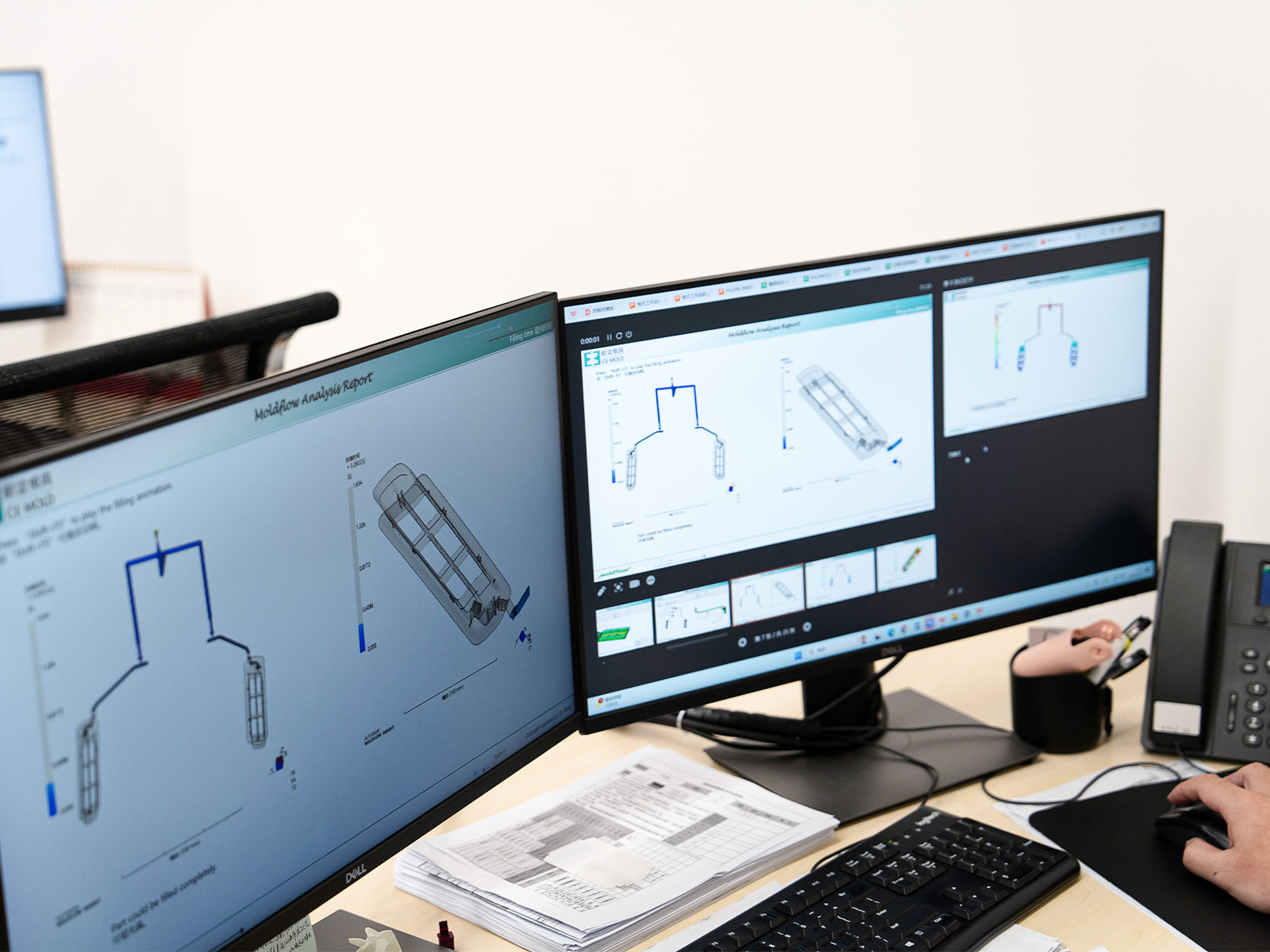

Advanced Digital Analysis

We leverage the latest digital tools to analyze and verify every mold and product. When needed, we perform moldflow, simulation, and fluid or aerodynamic analyses. Our approach relies on data to anticipate and solve potential issues, not on guesswork or past experience.

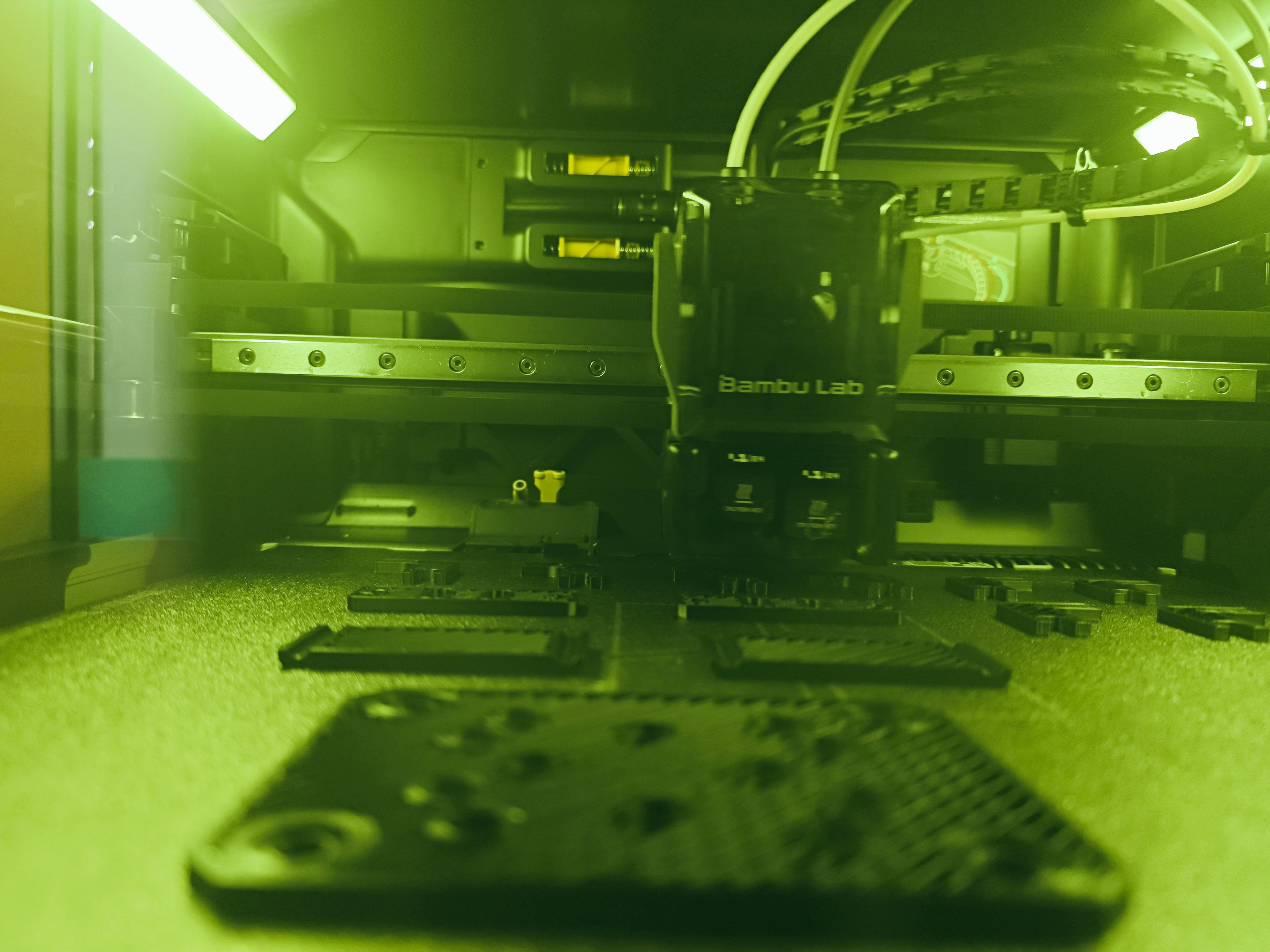

Design Verification with Prototyping

We have our own 3D printing and prototyping equipment to quickly verify design solutions for products, molds and other production tools. This ensures the effectiveness of each solution and reduces trial-and-error time as much as possible.

Designing Manufacturing for Success

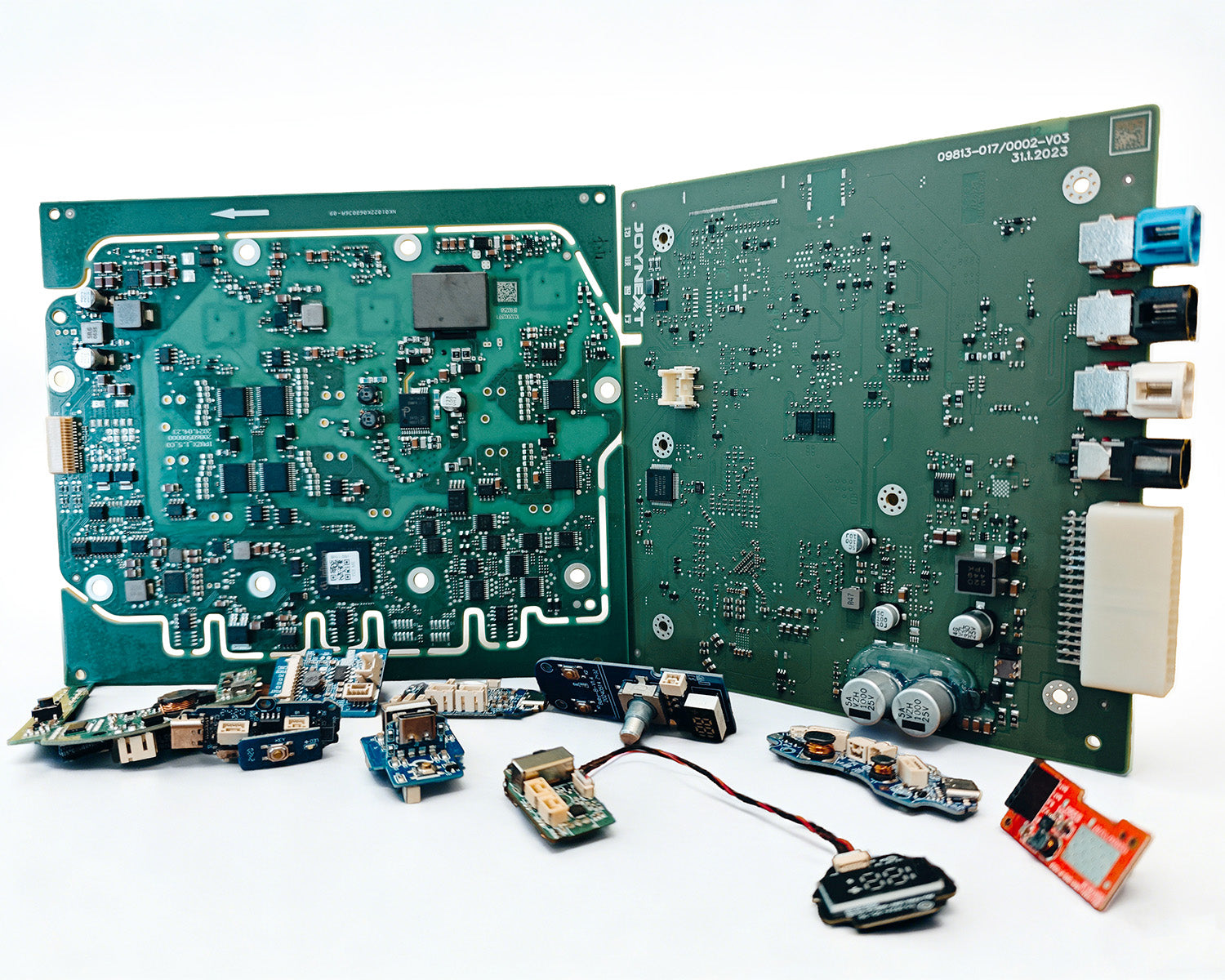

To ensure a smooth transition from mold design to mass production, manufacturing is engineered as a system, not handled as isolated steps. We operate with a dedicated manufacturing engineering structure that integrates process planning, automation, and execution control from the very beginning. Our team of over 40 engineers brings together hardware and software expertise, enabling coordinated decisions across tooling, processing, automation, and production flow. This integrated approach allows risks to be addressed early and manufacturing intent to remain consistent through scale-up.

When you work with us, you gain more than machining capacity. You gain a full-chain manufacturing partner built for deep collaboration and long-term production success.

Automation and Smart Manufacturing

In response to customer demands, we began exploring the design, manufacturing, and application of jigs, fixtures, gauges, and small-scale semi-automation 15 years ago. To date, we have invested nearly 70 million RMB in automation.

Today, we continue to invest in developing our automation and smart manufacturing capabilities, solving production pain points for customers, and providing direct value and future assurance.

Raw Materials

Excellent products start with excellent raw materials. Our global network of over 3,000 partners and agile supply chain ensures supply certainty, cost and technical optimization, and fast response to your production needs.

Excellent products start with excellent raw materials. We maintain a global network of over 3,000 partners and a preferred supplier matrix across industries and regions. This allows us to quickly respond to disruptions and match your product with the most suitable, cost-effective material—whether high-gloss consumer electronics, tough automotive plastics, or medical-grade compliant materials.

Our supply chain rhythm is aligned with your production needs. Strategic inventory, VMI, and a digital supply chain platform enable fast allocation for urgent orders, agile small-batch sampling during design, and seamless material supply during production ramp-up.

We go beyond buyer-supplier relationships through joint R&D with core partners. This allows us to develop custom materials, access new bio-based and high-performance options early, and optimize formulations at the molecular level for cost and performance. Our raw material supply chain is the invisible foundation of your product reliability, innovation, and competitiveness.

Excellent products start with excellent raw materials. We maintain a global network of over 3,000 partners and a preferred supplier matrix across industries and regions. This allows us to quickly respond to disruptions and match your product with the most suitable, cost-effective material—whether high-gloss consumer electronics, tough automotive plastics, or medical-grade compliant materials.

Our supply chain rhythm is aligned with your production needs. Strategic inventory, VMI, and a digital supply chain platform enable fast allocation for urgent orders, agile small-batch sampling during design, and seamless material supply during production ramp-up.

We go beyond buyer-supplier relationships through joint R&D with core partners. This allows us to develop custom materials, access new bio-based and high-performance options early, and optimize formulations at the molecular level for cost and performance. Our raw material supply chain is the invisible foundation of your product reliability, innovation, and competitiveness.

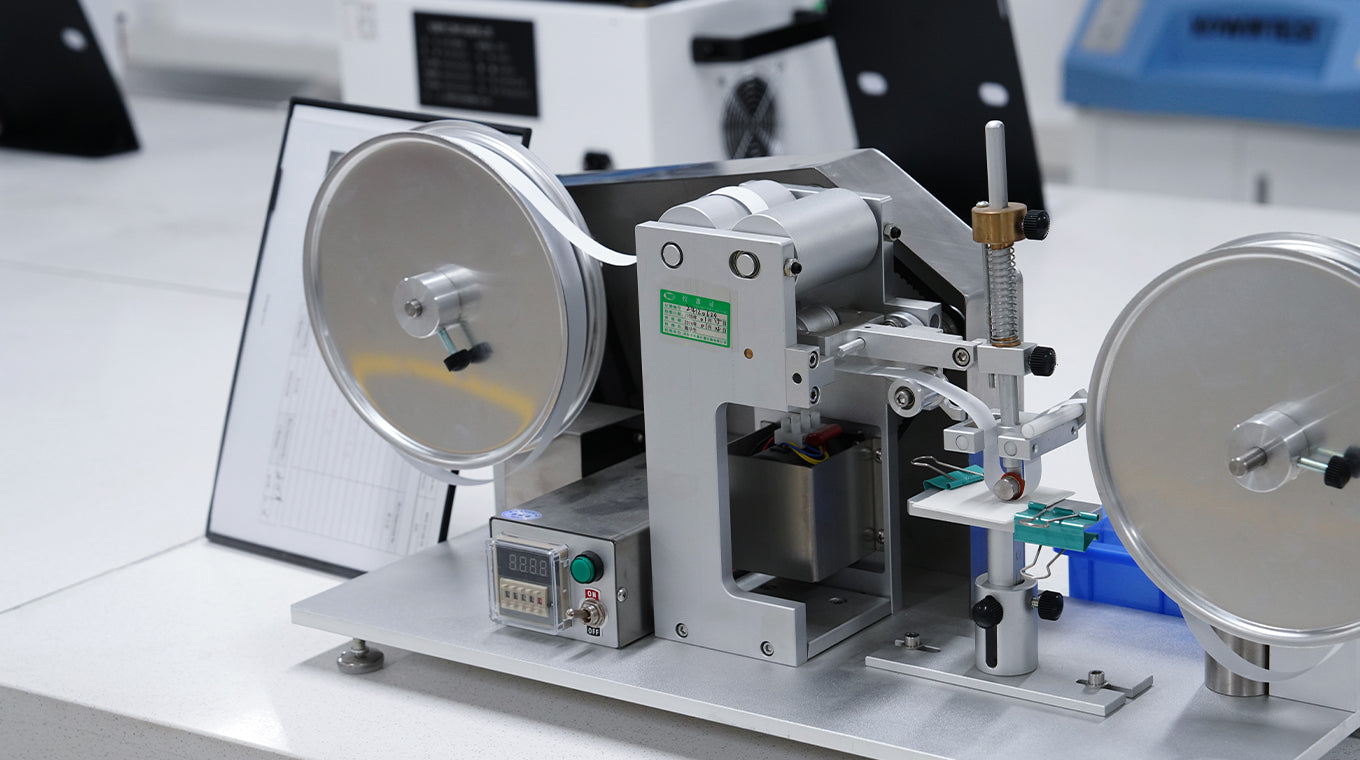

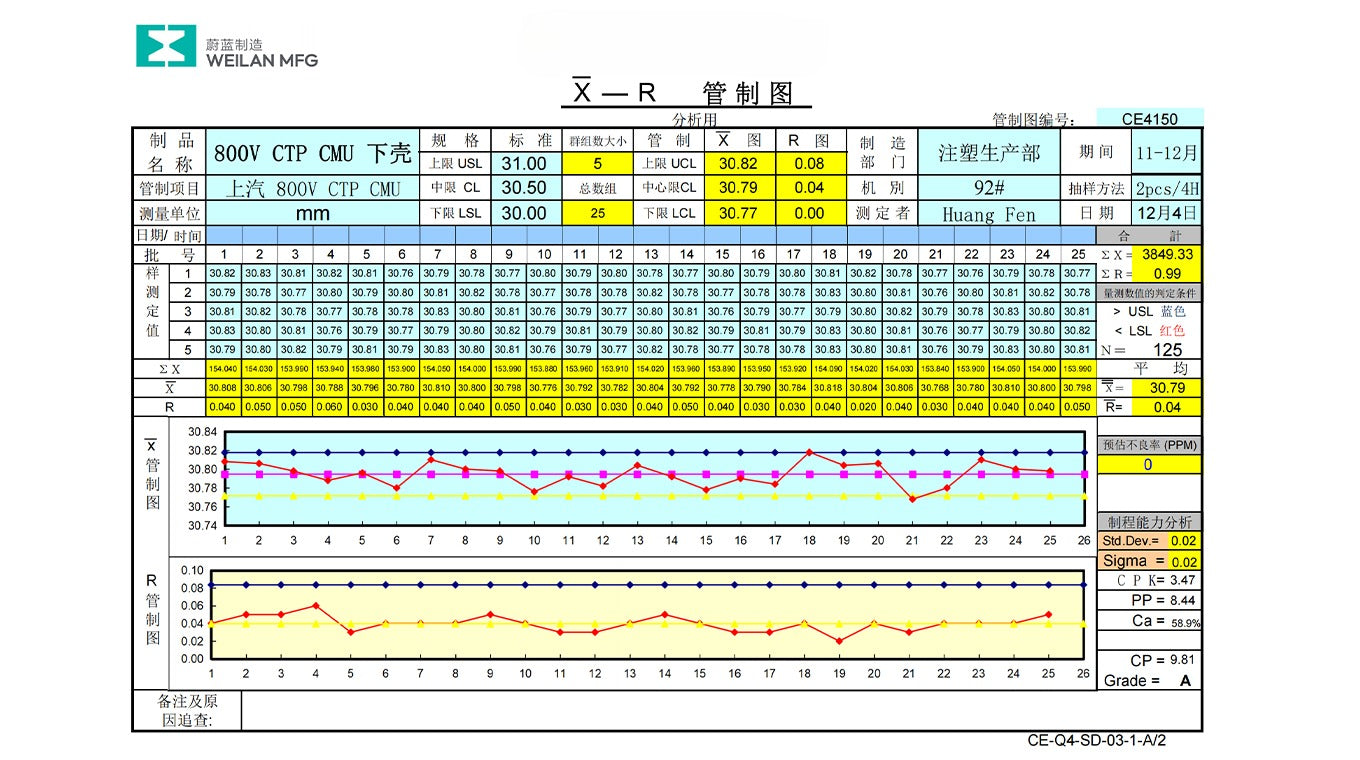

Quality Control

Beyond inspection, empowering manufacturing. We believe quality control is both a co-creator of excellent products and a gatekeeper of supply chain risk. Continuous investments in hardware and software strengthen our capabilities so customers can move forward with confidence.