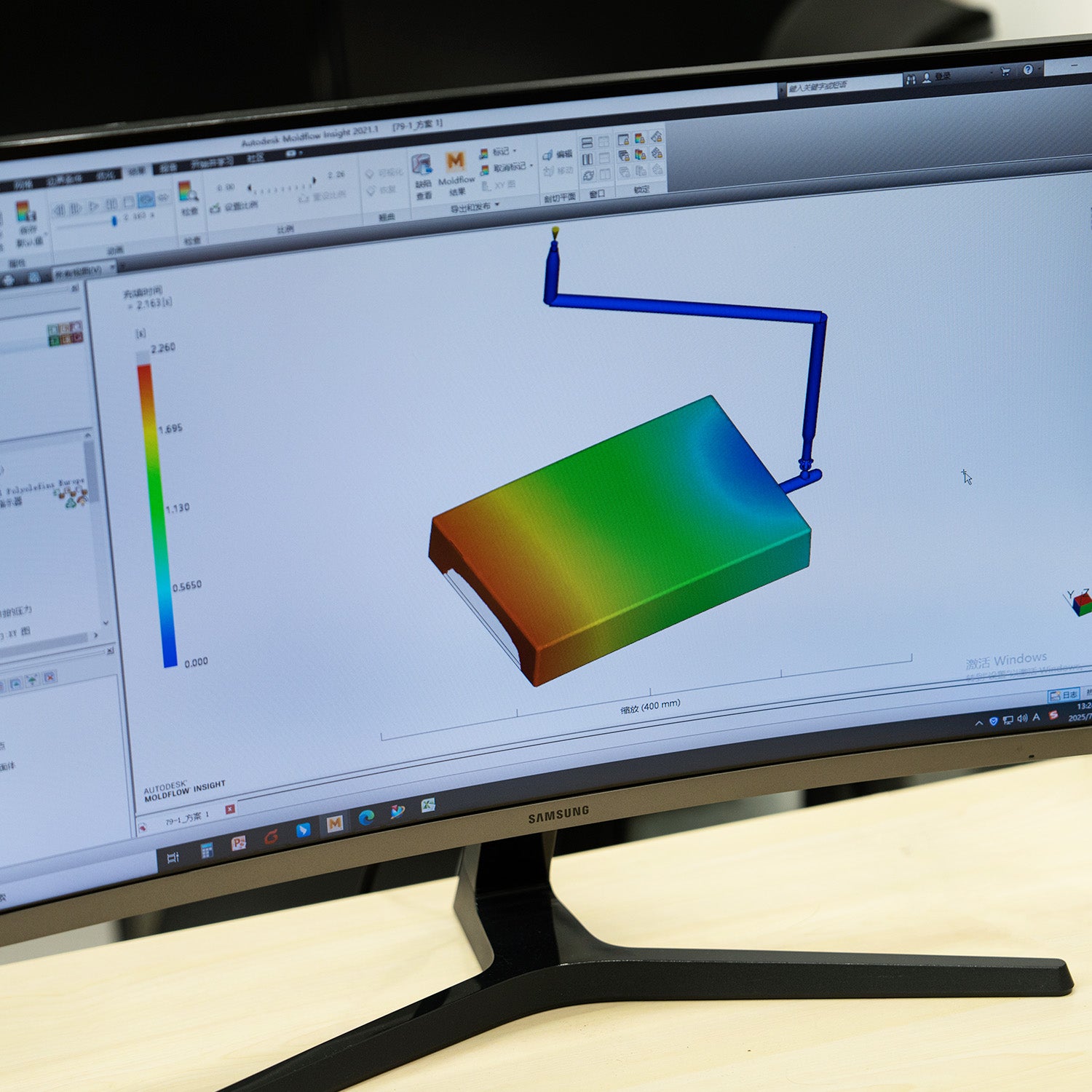

Critical mold behavior is defined at the design stage, not discovered during trials. Movements, tolerances, component interactions, and inspection logic are considered before steel is cut. Resolving complexity digitally reduces the need for corrective fitting and repeated trial adjustments, resulting in cleaner builds and a smoother transition into production.

Front-Loaded Engineering for Stable Mold Production

At our facility, mold manufacturing starts with in-depth engineering, not downstream corrections. We focus on mold design and project planning to address structural, processing, and production risks before machining begins. This approach produces molds with fewer unknowns, shorter validation cycles, and greater long-term stability.

Precision machining is about controlling complexity before it turns into risk. Machining accuracy comes from deliberate process planning, disciplined execution, and defined verification points. Every decision aims to create mold components that assemble predictably and perform consistently in production.

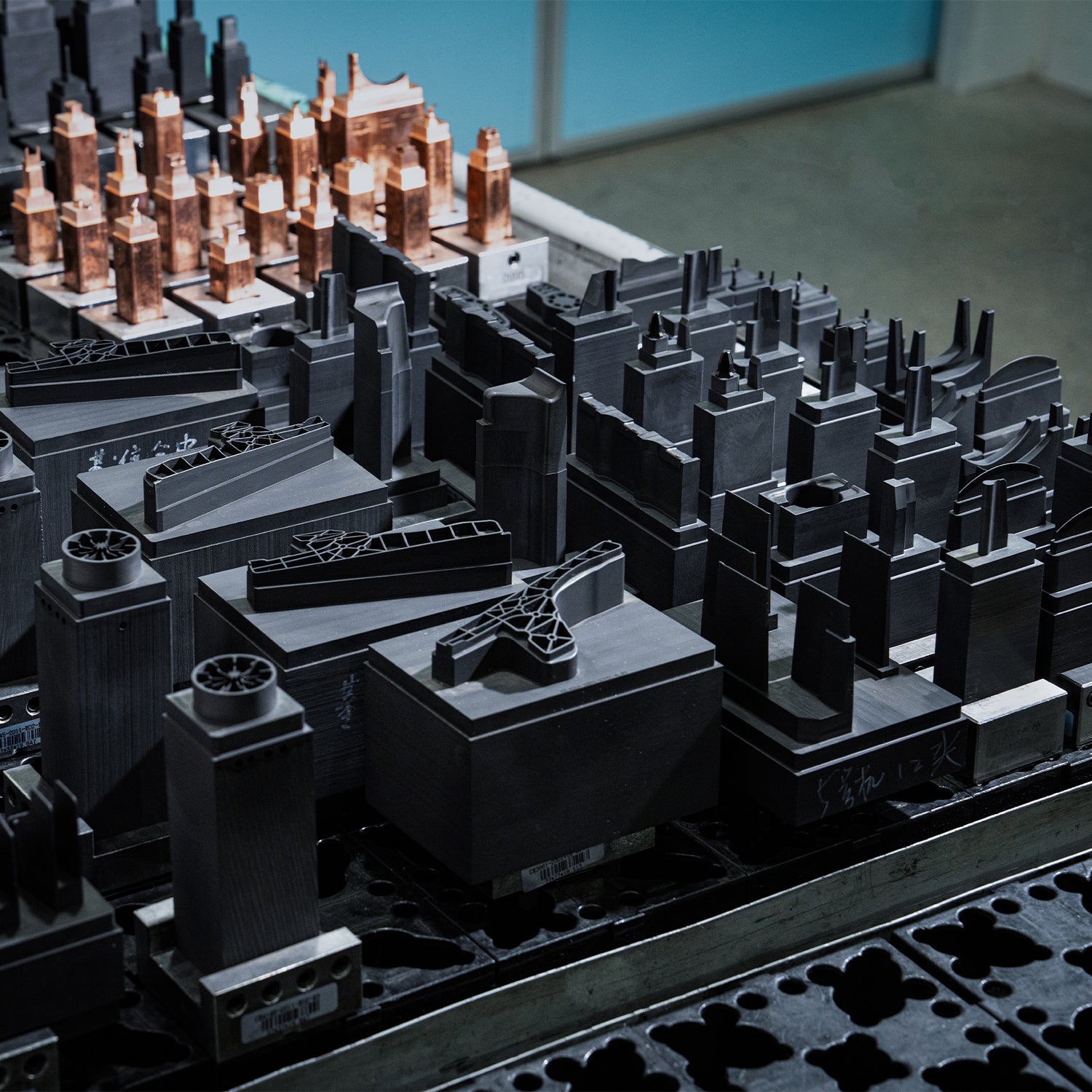

Machining sequences, fixtures, electrodes, and reference datums are fully defined before cutting begins. Each operation is planned to minimize variability between setups, machines, and shifts. This reduces on-the-spot decisions and prevents small deviations from affecting assembly or performance later.

Tight tolerances on fine features are treated with the same discipline as large structural components. Complex geometries and multi-directional machining are approached as integrated systems. Positional relationships remain stable through machining, handling, and assembly.

Graphite electrodes are used for faster, more stable EDM machining with finer surface finishes. Each electrode is tracked in our MES system with a unique identifier linking machining parameters, burn sequences, clamping setup, and inspection history. Operators scan the code to follow the workflow, ensuring consistent results across machines, shifts, and operators.

Key dimensions are verified at defined stages using ZEISS CMM systems. Inspection points and methods are planned during engineering so results guide the next operation. Early verification contains deviations before they affect assembly or trial outcomes.

Polishing: Predictable Mirror Surfaces

The quality of a mold surface directly determines the product’s appearance and feel. The process route is fully defined from the start, with standardized steps and measurements at each stage to ensure Ra values meet specifications. Strict adherence to digital models and operating procedures ensures consistent polishing and repeatable mirror-level finishes.

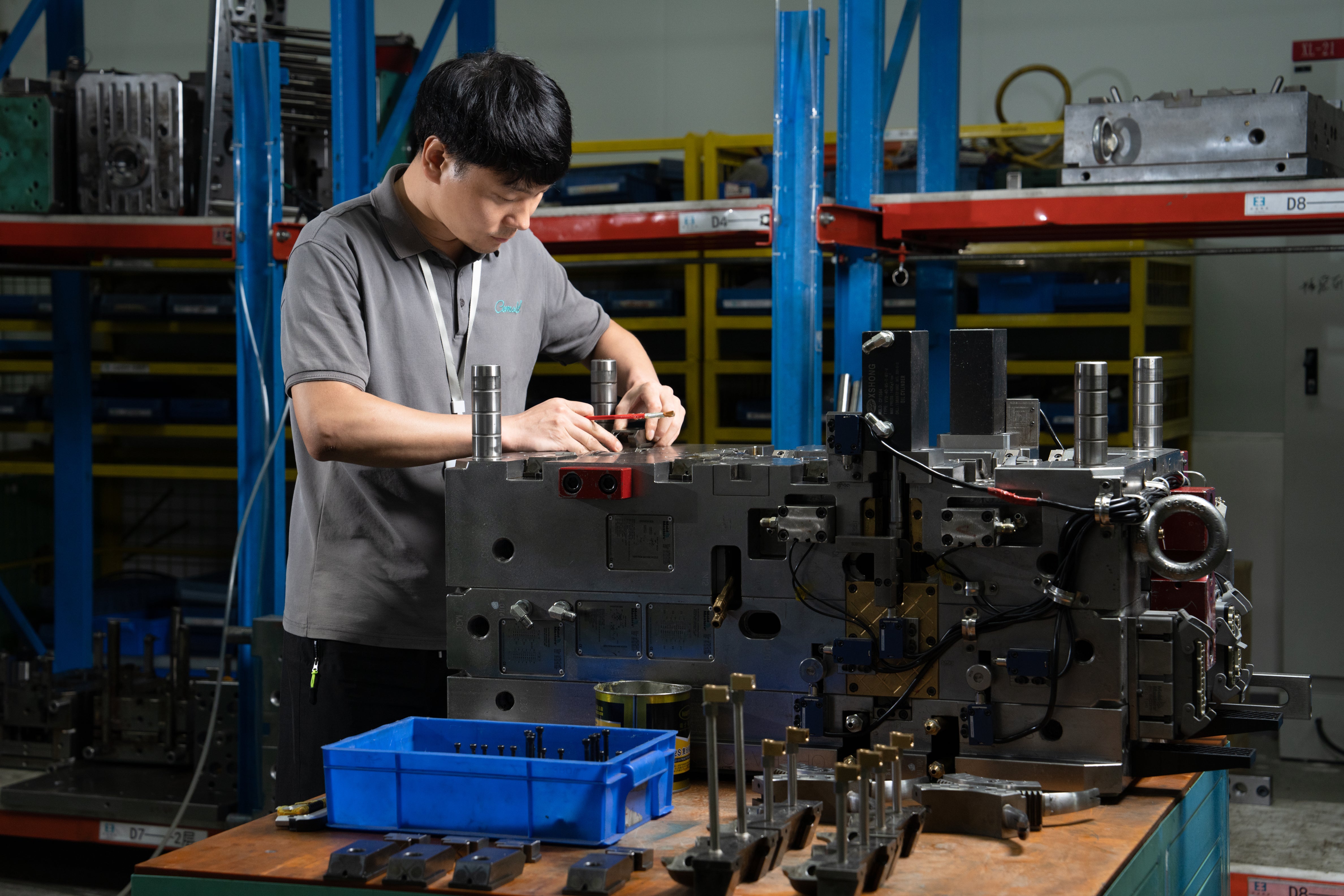

Assembly: Precision and Integration

Mold assembly is more than joining parts; it verifies overall mold function. Before machining, 3D CAD are used for interference checks and motion simulations to resolve fit and movement issues. Components undergo visual inspection and measurement review. Moving parts are checked with dial indicators and stroke tests for smooth operation and precise positioning. Electrical and heating systems are tested independently, while cooling and air circuits undergo high-pressure holding tests to ensure reliability and stable production. This process reduces setup time, accelerates production start-up, lowers trial counts, and shortens lead times.

Silicone Casting Inspection: Pre-Production Check

For critical molds, silicone casting inspections are performed at key stages to identify internal flaws. The inspection confirms that every detail meets design requirements, providing a reliable basis for production. Potential issues are resolved before injection, ensuring molds perform correctly the first time.

Mold Testing and Validation

Our goal is not just to pass a trial. We aim to ensure molds run stably in production. We follow a scientific approach to evaluate every mold. Our in-house equipment covers 40T–800T machines, high-speed and vertical, supporting 2K/3K multi-material, overmolding, IML, and gas-assisted processes. We aim to detect all potential issues in the first trial, eliminating risks before mass production.

First Trial Driven by Engineering Intent

Trial adjustments follow predefined engineering objectives, not personal preference. We validate mold behavior against the original design and Moldflow assumptions. This includes filling balance, warpage tendencies, venting efficiency, temperature control, mold actions, and part dimensions. Our approach exposes issues early rather than masking them for cosmetic results.

Extended Run for Production Stability

After the first trial, molds typically run continuously for 2–4 hours. This verifies part quality and mold stability over time. We monitor moving components, cavity surfaces, venting, and process consistency. The goal is to confirm the mold can operate reliably in long-term production, not just produce acceptable samples briefly. This step reduces downstream risk and ensures a smoother transition to mass production.