Standardized Process Control with Built-In Flexibility

Advanced Automation and Large-Scale Production

Across three specialized workshops, we operate 109 injection molding machines ranging from 40T to 800T, providing stable capacity for large-scale global production without resource conflicts. Centralized material feeding systems and high-precision Moldmaster temperature control ensure material purity and thermal stability, even for complex engineering plastics. With full robotic integration and standardized equipment, our automated production minimizes human variation and delivers consistent quality from the first shot to the last.

Overmolding

We understand the critical nature of interface adhesion. Our process ensures chemical bonding between dissimilar materials to prevent delamination under stress, enhancing grip and long-term sealing.

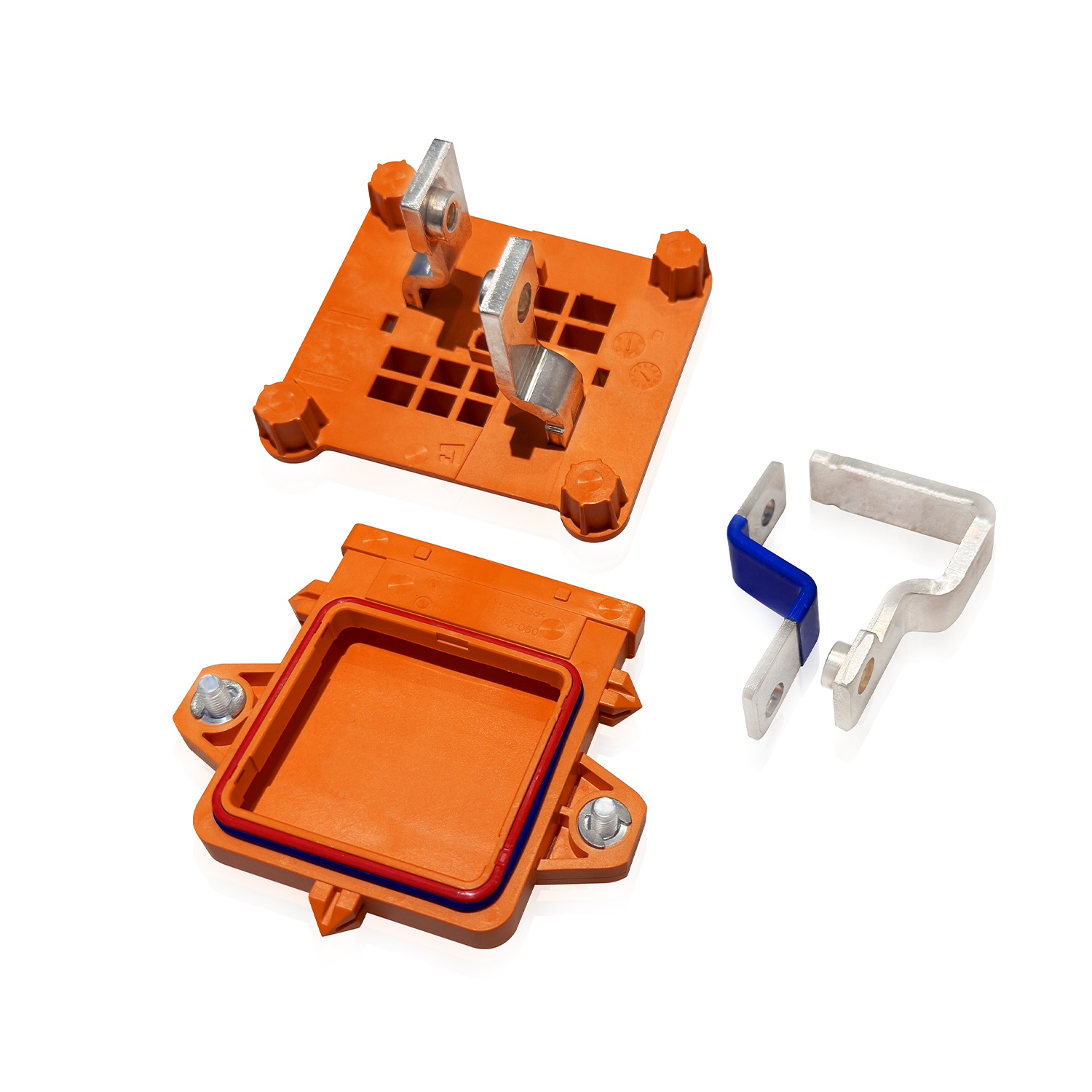

Insert Molding

More than just placing parts, we manage thermal expansion differentials. By controlling molding pressures and temperatures, we ensure metal inserts remain perfectly positioned without causing internal stress cracks in the plastic.

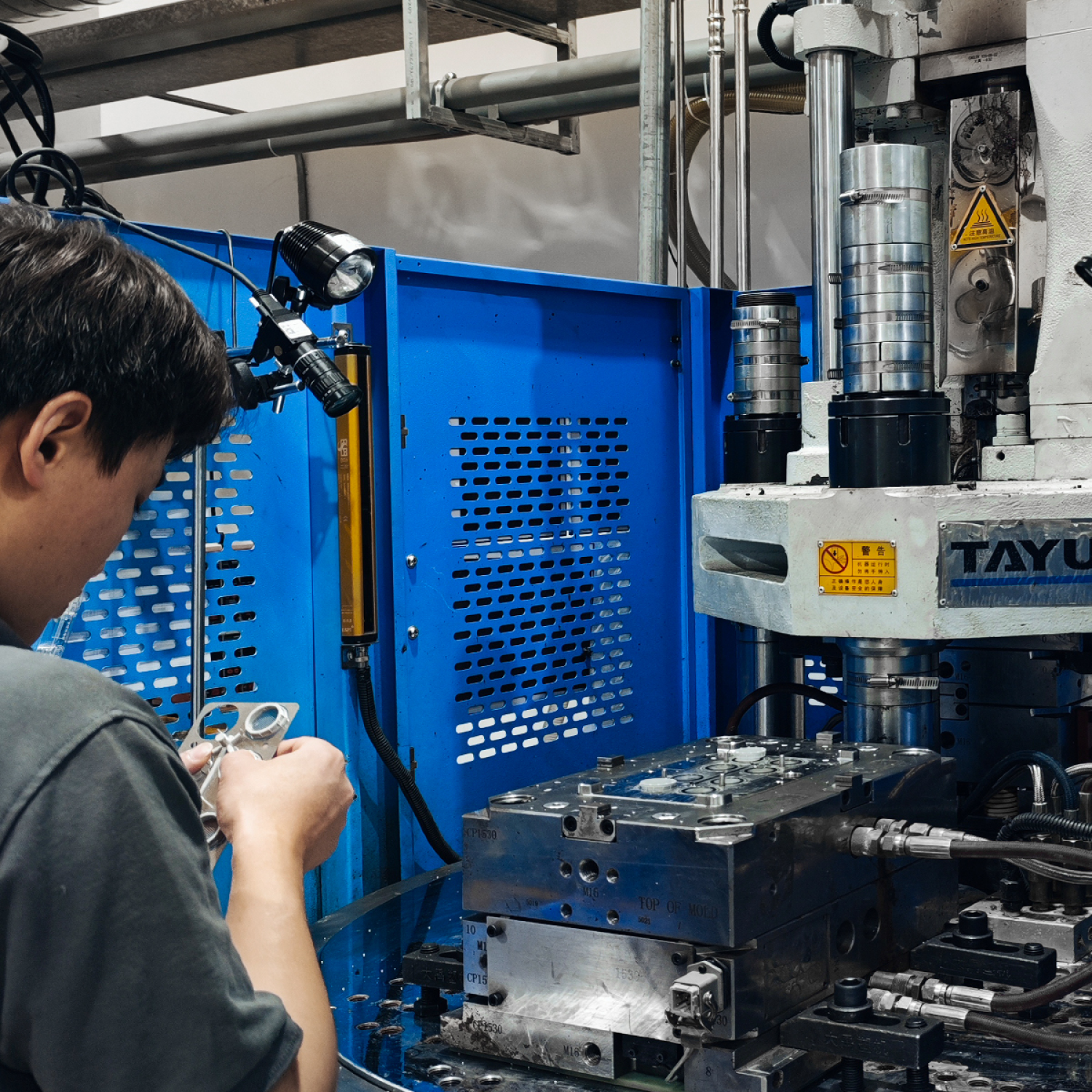

Vertical Injection Molding

Utilizing gravity-assisted alignment for complex inserts. This setup ensures that small, precision components stay securely in place during the injection cycle, delivering higher yield and reliability.

2K Multi-Shot

Solving complexity in a single automated cycle. We focus on the precision of the shut-off surfaces to eliminate flash between materials, delivering integrated parts without the need for secondary assembly.

In-Mold Labeling (IML)

Fusing graphics directly into the part’s DNA. We ensure the label and resin become one single entity, creating a surface that is far more resistant to chemicals and wear than traditional surface printing.